- Magazine

- Personal care and consumer goods

- From ‘Stick’ to ‘Slip’: How Viscoelastic Design Tunes Silicone Adhesives and Release Liners

From ‘Stick’ to ‘Slip’: How viscoelastic design tunes silicone adhesives and release liners

Silicones power everything from wound dressings and surgical tapes to labels and high‑temperature industrial tapes. This article explains how a single viscoelastic window connects pressure‑sensitive adhesives (PSAs), soft skin adhesives (SSAs) and release coatings (RCs), and how MQ resins fine‑tune performance.

Why this matters in self-adhesive materials?

From labels and tapes to feminine hygiene liners, from wearable medical devices to protective films for touchscreens, silicone coatings enable controlled release when needed and reliable adhesion when required. These behaviours emerge from the same viscoelastic fundamentals that can be measured, plotted and engineered.

The three silicone coating families

Release Coatings (RCs)

Pressure-Sensitive Adhesives (PSAs)

Soft Skin Adhesives (SSAs)

- Release Coatings (RCs): Ultra‑low surface‑energy layers applied to paper or film liners, enabling clean release for labels and hygiene product constructions.

- Pressure‑Sensitive Adhesives (PSAs): Silicone polymers blended with MQ resins for tack, peel and shear. Ideal where acrylates struggle, such as high temperatures or low‑energy substrates.

- Soft Skin Adhesives (SSAs): Lightly crosslinked silicone gels designed for uneven, moist or oily skin surfaces, enabling gentle removal for medical and consumer applications.

The viscoelastic window explained

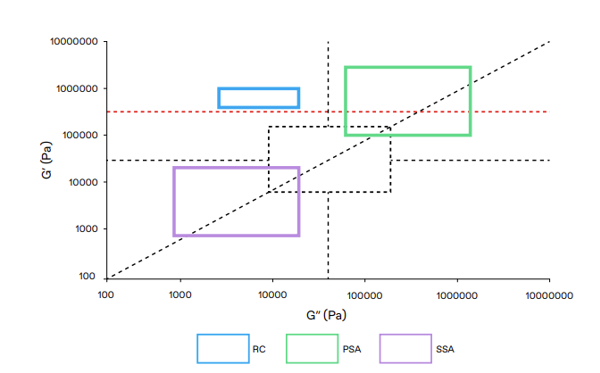

The viscoelastic window is based on four rheological measurements, the storage (G′) and loss (G″) moduli at low and high frequencies which together help predict how an adhesive will behave.

The storage modulus G′ reflects rigidity or elasticity, while the loss modulus G″ represents energy dissipation and viscous character.

According to the Dahlquist criterion, a low‑frequency G′ below 3×10⁵ Pa indicates good tack. A material’s position relative to the G′–G″ crossover line also predicts how cleanly it will detach, with formulations near this line typically removing without cohesive failure. Within this framework, RCs fall in a region of high G′ and low G″, reflecting their rigidity; general‑purpose PSAs sit in a central zone balancing tack and cohesion; and SSAs, characterized by lower G′ and G″ values, offer easy bonding and gentle removal.

Position of a viscoelastic window on the loss–storage plot correlated to the type of material: RCs, PSAs and SSAs

Your chemical toolbox for tuning performance

Because RCs, PSAs and SSAs share similar silicone chemistry, a formulation’s viscoelastic window can be shifted by adjusting:

- Molecular weight: Higher MW increases elasticity (higher G′).

- Crosslinking density: More crosslinks strengthen the network cohesion.

- Coatweight: Adjusted to reach specific slip or stick perfomances (RC: 0.1–2 μm, PSA: 10–50 μm, SSA: 100–200 μm).

- MQ resins content: The most precise lever for adjusting tack, peel and shear of PSAs and SSAs for controlling release tightness in RCs.

Pairing adhesives and liners

Silicone PSAs can chemically interact with standard silicone release coatings, causing unstable release. This is why fluorosilicone release liners are typically preferred for silicone PSAs. SSAs often release well from non‑siliconised or embossed films; hybrid SSAs may require siliconised or fluorosilicone liners.

What this means for brands and converters

For brands and converters, this means faster decisions, fewer formulation risks, and a clearer path to creating products that perform flawlessly from production to end‑use. By understanding how viscoelastic behavior drives both adhesion and release, you can confidently choose the right silicone system. Elkem’s long experience helps tailor the right adhesive–release coating pair for each application. Mastery of all silicone coating types and chemical tools enables designing solutions anywhere from strong adhesion (“stick”) to easy release (“slip”).