- Magazine

- Innovation & sustainability

- Is silicone sustainable? Understanding its carbon footprint and life-cycle impact

Is silicone sustainable? Understanding its carbon footprint and life-cycle impact

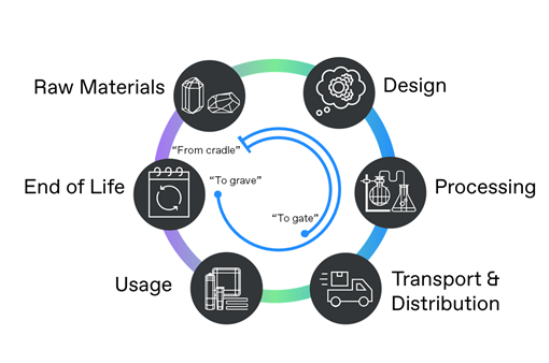

Customer and consumer demand for environmentally responsible products is growing. Many ask, ‘Is silicone sustainable?’ Yet the ability to discern which products are more environmentally responsible requires greater understanding and transparency about how materials are made, used and disposed of.

Is silicone sustainable? Are silicone materials a responsible choice?

Driven by global initiatives like the Paris Agreement, the Global Silicone Council (GSC) sought to answer this question by commissioning a study to evaluate the GHG impact of silicone materials across multiple applications and industries in Central Europe, North America and Japan. The study found that the use of advanced silicone materials deliver an average of 14 times greater decarbonization benefits than their production and end-of-life impacts. This means that for every ton of CO₂ emitted by producing silicones, it is outweighed by 14 tons of CO₂ reductions.

GHG reductions delivered by silicone materials are vital to a low-carbon society. That is why responsible producers like Elkem are making every effort to multiply their benefits by reducing the footprint to produce these materials. And we have developed industry-leading tools that enable customers to make more sustainable sourcing of silicones decisions in product design.

How are silicones made and are they sustainably produced?

Unlike many plastic materials derived from fossil fuels like oil, coal, and natural gas, silicones are synthetic polymers with a silicon–oxygen backbone. They offer an amazing variety of properties and applications, from cosmetics to sealants.

Silicone manufacturing begins with quartz, an abundant, naturally occurring mineral resource. Quartz, silica and silicates are compounds of silicon and oxygen, which form a vast group of minerals that make up over 90% of the Earth's crust. That makes silicon the second most abundant material on earth, behind oxygen.

However, the selection of a supplier can have a dramatic impact on how sustainably silicones are manufactured. That’s why it is important to know the basic process and how suppliers like Elkem are optimizing the footprint of silicones by producing them in carbon-advantaged locations using environmentally friendly technologies.

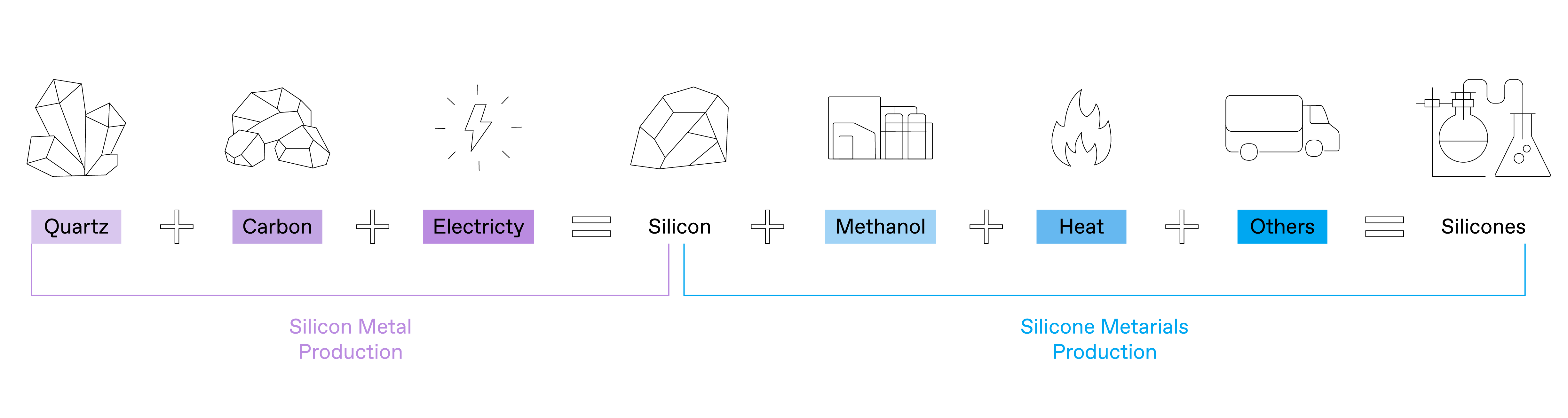

The process used to make a wide variety of silicones is shown in its simplest form below in two distinct phases.

The first phase, as shown in the purple shading, is the production of metallurgical-grade silicon. The carbothermal reduction reaction produces silicon by mixing quartz with carbon-containing material (coal, coke, charcoal, or woodchips) and heating it. The resulting silicon has unique properties as a semiconducting metalloid element, which makes it a vital a raw material precursor for the production of silicones.

The silicon smelting operation represents one of the most energy-intensive steps in the manufacturing process. Key findings in the 2024 Update of the Si-Chemistry Carbon Balance Project SILICAB 2 Nutshell Report reveal that silicon represents up to 67% of GHG emissions in methyl siloxanes, a silicon derivative and precursor in the production of many silicone materials.

The second phase, as shown in the blue shading, is the production of a wide variety of silicon-derivatives (reactive silanes, siloxanes and silicone materials). This part of the manufacturing process uses silicon, methanol and other raw materials specifically chosen for the end-use application. However, it is important to note that the methanol production/supply represents another CO₂-intensive raw material in the footprint of silicone production.

At Elkem we’re involved at all stages of the manufacturing process, from the extraction of quartz at our facilities in Norway, to the production of metallurgical-grade silicon, and its conversion to silicone polymers. This provides us with insights into all aspects of the ‘value chain, allowing us to adapt to new trends as well as develop and adopt new technologies efficiently.

Why is silicon metal production so energy intensive?

he carbothermal reduction requires that the quartz and carbon-containing materials be heated in a submerged electric arc furnace at temperatures of 1500–2000 °C. This is at or above the temperature of iron and steel smelting, but below the temperature of tungsten smelting. You can dig deeper into the chemistry here.1

Once metallurgical-grade silicon is produced, it can be further refined to produce higher-purity grades if needed. The purified silicon can then be converted to methylchlorosilanes and polydimethylsiloxane, reactive materials that enable the production of the wide variety of silicone materials used in daily life.

How are lower-carbon silicones produced?

Strategic sourcing and responsible manufacturing can significantly reduce the footprint of silicon metal and silicone manufacturing. Power agreements that leverage a highly renewable power grid can dramatically reduce the footprint of silicon smelting. Strategically locating manufacturing operations can create carbon-advantaged silicones by tapping into grids that are rich in the use of solar, hydro and wind power. Such efforts by silicone suppliers can help customers meet their Scope 3 emissions reduction targets and lower their own product carbon footprint (PCF), positioning them to meet growing demand for environmentally friendly products.

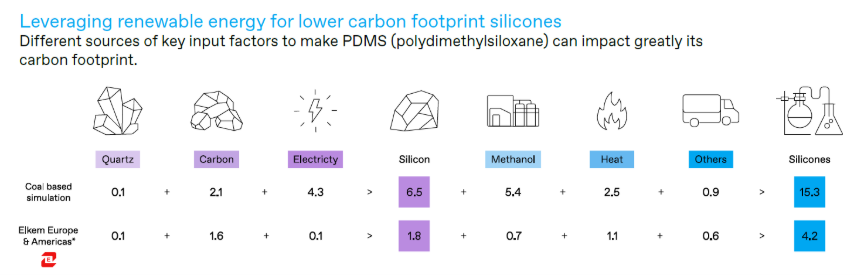

For example, the illustration below shows the significant footprint reductions that are possible through strategically sourcing clean energy, carbon and methanol.

Elkem silicones manufactured in Europe and the Americas have achieved one of the lowest carbon footprints in the silicones industry – approximately 30% lower than the industry average as calculated by the Global Silicones Council. This is mostly due to the high share of hydropower and biocarbon the Company uses to manufacture silicon metal. For instance, Elkem’s operations in Norway that use hydropower have achieved the lowest carbon footprint silicon metal production on the planet. In addition, our European downstream plants use highly decarbonized electricity.

In contrast, coal-based producers of silicones have a footprint above the industry average and more than 3 times higher than carbon-advantaged silicones from Elkem Europe and the Americas.

How can we adopt more sustainable silicone sourcing?

Transparency across the value chain is vital in sustainable sourcing of silicones. sustainable sourcing of silicones is a strategic priority for Elkem, spanning raw materials, energy, goods, services and logistics. We have governance in place that drives environmentally friendly and healthy business practices, setting high standards for our suppliers and ourselves.

Sustainability and innovation go hand in hand at Elkem. We are doing our part to produce lower-carbon silicones with:

- Responsible use of hydropower – Globally, Elkem sources more than 80% of its electricity from hydropower.

- Transparency that supports decarbonization

Transparency is built upon reporting and measurements that can be trusted to drive meaningful reductions. This information also helps prioritize investments. That is why Elkem developed FootSi, a footprint calculator based on GHG protocol recommendations. FootSi is used to calculate accurate carbon footprint data silicone products. This data can be provided upon request to customers, enabling downstream users to calculate their Scope 3 emissions with accuracy, supporting their decarbonization roadmap and providing insight for supplier decisions.

- Innovation policy that keeps sustainability front and center – Elkem collaborates closely with customers to accelerate sustainable product development and enable more accurate product life cycle analysis (LCA) in support of a circular, lower carbon economy. We use Sustainable Portfolio Management (SPM) tools to integrate sustainability into business decisions, anticipating risks and opportunities in the product portfolio. Developing better solutions together in a timely manner across the value chain is a key pilar of Safe and Sustainable by Design (SSbD) approach.

We’re proud to share some examples of our Innovation policy in action:

- Our Test Center in Kristiansand, Norway, completed the first pilot phase of groundbreaking Elkem Sicalo® (Silicon production with carbon looping) project, which aims to eliminate all CO₂ emissions from silicon production. Read more about the NOK grant received from Enova and how this technology, if successfully implemented in all European production of silicon and manganese, could save 33 million tonnes of CO₂ emissions per year in 2050.

- Our Rana facility in Northern Norway completed the world’s first pilot for carbon capture and storage (CCS) at a smelter. The high capture rates of up to 95%, combined with low amine degradation, proved the technical effectiveness of the technology. Carbon capture, along with increasing the use of biocarbon, can potentially contribute significantly towards our global climate strategy of reducing emissions towards net zero. In fact, some of the captured CO₂ from Rana has the potential to be biogenic, meaning that there is potential for negative emissions.

- Elkem’s Sircle™ portfolio of eco-designed products reduce fossil use and have a lower carbon footprint by including bio-based or recycled content. We will be sharing more about our extensive Sircle™ portfolio and silicones recycling successes very soon. These efforts will help Elkem customers deliver more sustainable solutions to the market, anticipate future regulations and rapidly decrease their scope 3 emissions while making no compromise on performance.

Elkem believes that companies that act responsibly will be successful in the long term, bringing benefits to our customers, consumers and our planet. We are working to develop products and provide the transparency needed for transition to a low-carbon society.