- Magazine

- Trainee Blog

- From the everyday life at a plant to an R&D environment

From the everyday life at a plant to an R&D environment

For the last 5 months, I have had my third trainee placement in the R&D department of Elkem Silicon Materials (ESM) in Kristiansand. Now that the summer holidays are approaching, so is the end of my trainee adventure and the start of a permanent position in Elkem.

In this blog post I would like to give you some info about ESM in Kristiansand, followed by an insight in what a trainee period within R&D can offer. Lastly I will describe my job position after ending the trainee program.

ESM is in fact the world’s leading supplier of microsilica – an extremely fine-grained powder consisting of spherical particles of amorphous silicon dioxide. A fun fact worth mentioning is that the world’s tallest building, Burj Khalifa (828 m), contains 25.000 tons of Elkem Microsilica®! This powder was once a non-valuable byproduct from the exhaust gases exiting the silicon smelting furnaces and was deposited. Now both microsilica and microsilica based products are sold to all parts of the world with a wide range of functionalities, such as increasing strength in concrete, improving flow properties of advanced refractory castables, improving flame retardancy in polymers and controlling gas migration in oil wells. It actually exists a requirement from the Norwegian Public Roads Administration that Elkem Microsilica® is added to all concrete used for infrastructure applications. The major business areas of the ESM department in Kristiansand, also referred to as just “Elkem Materials”, are sourcing, further processing of microsilica to obtain specialized products and extensive global sales.

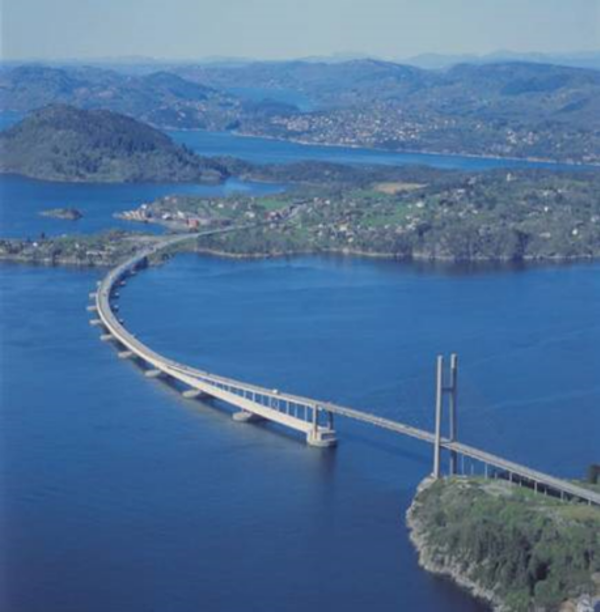

Picture description: Examples of tall buildings and marine bridges containing Elkem Microsilica®; Burj Khalifa, Nordhordaland Bridge and Petronas Towers.

During my stay in Elkem Materials I have been part of a group consisting of R&D scientists with different specialty areas in the department of technology. One common focus area has been to increase our fundamental knowledge of details around the formation of silica fume from furnace reactions. This type of work we call the Incubator Concept, and the task immediately brought my thoughts back to the hours spent on literature studies when writing my master’s thesis… but what an interesting topic! Comprehensive studies of furnace reactions followed by having enlightening discussions and sharing hypotheses with the group of scientists was a knowledge enriching and fun experience.

Picture description: Various microsilica grades with a colour range from off-white to dark-grey.

I have also been working with microsilica related technical support to one of the plants within ESM. This task has provided me some practical work by learning and performing various analyses on microsilica samples with laboratory instruments available at Elkem Materials. I have also had the pleasure of working with verification of a material balance model for production of microsilica from a given furnace. For this task, quite many input variables to the furnace had to be considered, such as raw materials and furnace operation parameters.

In August, I will be starting in a position at Elkem Thamshavn in Orkanger, managing the processes of crushing, screening and packing of silicon together with the filtering and packing of microsilica. I am excited and looking forward to be part of the production team.