- Trainee Blog

- From southern battery labs to arctic silicon smelters

From southern battery labs to arctic silicon smelters

After graduating University, I had a fairly broad spectrum of fields I could apply in for jobs. Because I am Austrian and had been on exchange in both Norway and Sweden before, I looked for jobs in all three countries. The decision where to move and what to work with was quite a big one. When I got the call from Elkem that I could be one of the five trainees starting in 2022, it was thus not an easy decision, but I don’t regret it! The trainee programme seemed like an adventure, and kind of a “soft start” on the journey from being in education to working in industry. This is because as a trainee, you are expected to learn and to ask a lot of questions. You are not expected to know everything, and colleagues are usually very happy to help you find footing. It is also a good transition from living a flexible student life including exchanges abroad to eventually settling down at one workplace for a longer time, since trainees are expected to move around to three different placements during the programme.

The company Elkem also seemed interesting with all kinds of material science- and engineering-related challenges to take on. I liked the idea of trying to work with different tasks and teams, both in order to gain experience and to get a better idea of what I want to work with in the long term.

On northern Europe's longest via ferrata in Setesdal

|

Working in the glovebox at Vianode Technology Center

|

Because I was already done with university and couldn’t wait for the start-up of the trainee-programme in August 2022, I got a temporary position at Vianode in Kristiansand from January 2022. This is where I also spent my first trainee-rotation, which made it sort of an extended first rotation. Vianode started as a project within Elkem and recently became a partly Elkem-owned company which is still inside Elkem’s trainee-programme at the point of writing this blog post. It aims to become one the major players in synthetic graphite production. This graphite powder is needed in ever greater quantities now for lithium-ion batteries, as the EV-market is booming.

I was very happy about spending a lot of time at this Elkem-born start-up. It felt like getting the best of both worlds – the exciting atmosphere of a start-up, with the backbone and support of a big and experienced company like Elkem. In the R&D-team at Vianode my work was quite academic. The project I worked on was about modifying the surface of the graphite particles to enhance fast-charging capabilities of the material. I did everything from experiments in a lab, to material characterisation of the samples, to analysing the results and planning new experiments. For me as a fresh graduate, it was a joy to work in this fantastic young and international team. The insight I got into the processes used at Vianode, including the core process – graphitization at extremely high temperatures – was exciting.

I was even there to experience the opening of the new Vianode Technology Center just outside Elkem Fiskaa Teknologipark and setting up all new lab equipment there. My entry into the working world was also made even better by my supportive coach Navaneethan.

In spring of 2023, it was time to move on to my second rotation, at Elkem Salten. This was the perfect time to take a roadtrip up north. Because I spent six months on student exchange as a teenager in the same region, it was a bit like coming back home for me. The coast around Kristiansand is nice, but nothing beats ski trips, climbing and hiking in the mountains in northern Norway – sorry, Sørlandet ;)

The summer weather has even allowed us to enjoy relaxing on the beautiful beaches here north of the arctic circle.

The “seven sisters” along the roadtrip from Kristiansand to Salten (note: this is not the main road ;))

|

A beautiful beach on a warm summer’s day near Bodø

|

While I am familiar with the surrounding area here, it has been quite a transition for me at work. From research and development at Vianode, I came to a smelting plant in Salten centred around one main product – silicon. Here, production is going on 24/7. In the beginning, I joined tapping and the control room for several shifts. No matter when you come to work or leave, the next shift of competent operators is keeping the furnaces going, like giant steel animals that have to be fed with just the right “food”, and that need constant care. The metallurgists know their furnaces with their “tempers”, with all the streams of data letting them know about their current “moods”.

The projects I am taking part in here are connected to measuring, digitalization, and process control. They are about new sensors which will measure particle size and moisture of raw materials. I am also taking part in a project for a mass-energy balance model of the furnace.

All these measurements and numbers will give the metallurgists a better idea of what is happening inside their furnaces, hence improving the control over the process, which again improves productivity for their work and the plant.

My days at the plant are a mix of work at the computer, hands-on tasks, and coordinating with all kinds of different parties both on-site and at other locations.

I am excited to see my work come to use during my stay here. The feeling of your own contributions making a positive impact is quite satisfying, and Elkem’s trainee programme gives many opportunities for it.

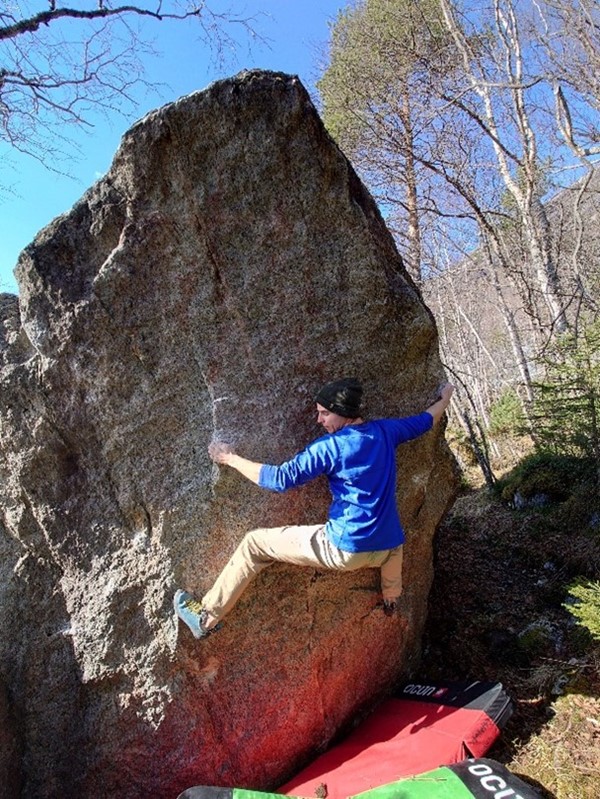

In my free-time, I am enjoying nature and culture around here – everything from climbing and skiing in these amazing surroundings with my fellow trainee Johannes and other friends, to classical concerts in the picturesque Lofoten islands.

At a great bouldering spot just 5 minutes from work in Salten

|

Tracks in the powder from my friends and me on a ski tour

|