- Magazine

- Trainee Blog

- Working with digitalisation

Working with digitalisation

After finishing a great trainee period at Elkem Silicones in France, my journey went back to Norway and Kristiansand. I got the opportunity to work for Elkem Foundry with data analysis and data mining. With this, I was able to take part in exploring some of the possibilities of the new and enlarged focus on digitalisation. Digitalisation is a major tool to increase profitability.

Elkem, like most other industrial companies, has in the recent years increased the focus on digitalisation. In the last year it has been on the top 3 priorities from the corporate board. Only a minor part of the measured and stored operational data is being used to make critical decisions. Currently, the data mostly tells us what happened yesterday, instead of telling us what will happen tomorrow.

These days, there are so many buzzwords in the field of digitalisation. Big data, machine learning, artificial intelligence. So how will Elkem take these relatively new tools into use? Previously, the limiting factor was often computing power. Now, this is rarely a problem anymore. It is more a challenge of figuring out how to utilise this large computing power to tell us as much as possible about Elkem’s processes.

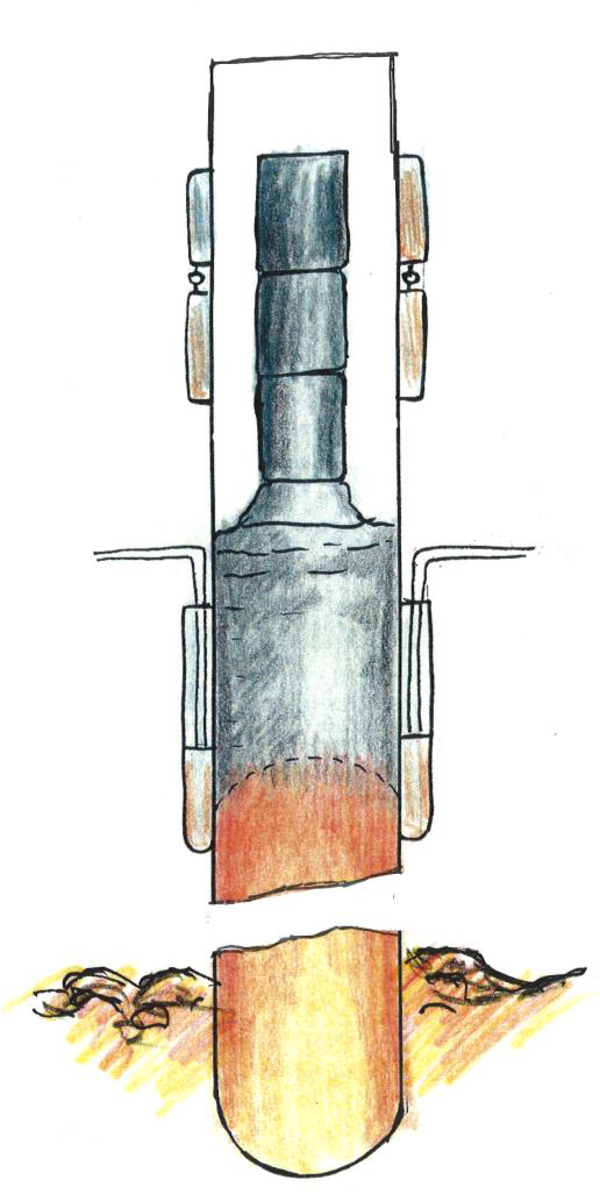

What I have been doing is exactly to try to utilise a lot of the stored data from the process. More specifically, my main case was to study, explore and analyse process data from Elkem Iceland with focus on electrode hard breakages. For me, this meant that I had to learn to programme in a new language and learn about the furnace process, and especially about electrodes. Since I had never worked with a furnace and never worked with programming before, it was a lot to learn. As a start, I got to go to London and attend a course in multivariate analysis. This was a great kickstart where I learnt the basic principles of multivariate analysis and the different methods that can be used to handle, analyse and predict. Later, I went to Iceland to work with process metallurgists and they taught me everything I know about their furnace processes. They also taught me how I could access and use the process data and advised me which data and variables I should use for the analysis.

Diving into a completely new subject was challenging, but with great support from engineers at both Elkem Foundry, Elkem Technology and Elkem Carbon, in addition to an external partner, I have learned a lot and it shows that as a trainee you have the possibility to work with new subjects and develop to get a broader knowledge for future work tasks.

Now my time as a trainee is coming to an end. It has truly been a wonderful experience and a great start of my work life. In every place I have worked I have learnt so much and I think all of it will be useful in my future work. When I finish as a trainee I am fortunate to start working at Elkem Technology for the Automation and information systems department where I will continue working with data analysis and digitalisation projects. I really look forward to my new work challenges.