- Magazine

- Trainee Blog

- Practical metallurgy, data analysis and teamwork

Practical metallurgy, data analysis and teamwork

You are probably interested in Elkem’s Trainee program, if you read this. If you consider applying for a trainee position yourself, I would tell you to do it! My impression is that you will be taken good care of, you will learn a lot and get to contribute in development of a better and greener process industry, regardless of your background. If you are wondering if the Trainee program is worth it in the long run, for Elkem, I would say yes! I started as a trainee only a few months ago and I have learned more about practical metallurgy, data analysis and teamwork than any master at university could do by itself. I think the next two years will make me a better employee, and the colleges and interesting projects makes me want to stay within the company. If you wonder if I

enjoy my days at Elkem Thamshavn; I guess you already know the answer.

Elkem is part of an energy demanding industry, which was known to not only pollute on a global scale, but also on a local scale. The areas around metal industry in Norway used to be covered in dust and smoke, but the industry have developed and the dust from silicon furnaces is now being captured and sold as a valuable product. Production of silicon do require a lot of energy and the process result in emission of large amounts of CO₂, but there is a constant improvement on this area.

I have my first trainee period at Thamshavn, which produce some of the world’s greenest silicon, if not the greenest. Thamshavn have a huge energy recovery system, converting heat in the off gas to electrical energy. Another action towards a greener product is use of bio carbon as a raw material. Elkem’s overall goal is to increase use of bio carbon from 20 to 40wt.% of carbon materials by 2030. There is a huge potential to reduce emission within Elkem, and the current effort put into this is equally high. This is an exciting journey to be a part of!

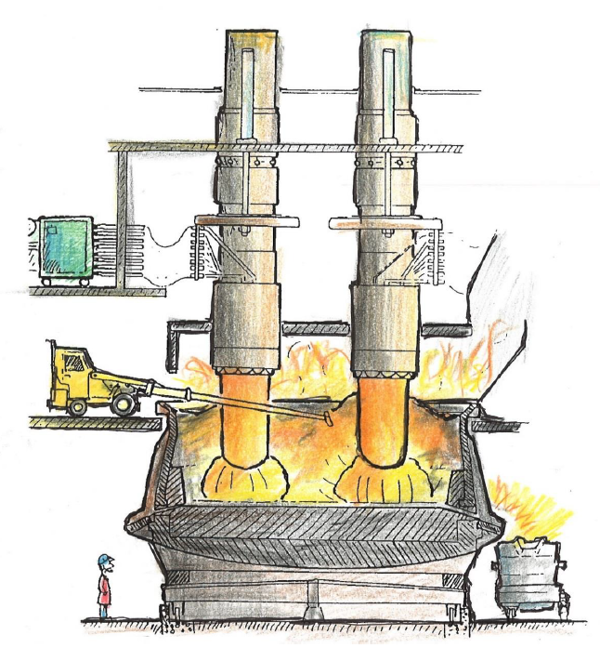

Figure 1: Stocking of one of the furnaces at Thamshavn.

I thought I knew the basics of silicon production before starting as a trainee at Thamshavn, but it turned out it was way more complex than expected. There is a huge gap between theory and practice, even though practice is based on theory. I was lucky enough to work a few shifts in the beginning, to gain some practical experience, in addition to getting to know more people working at different areas. The learning curve was steep. Electrode movement, tapping rate, holder position, tip position, “kvartsing”, “klumping” and “lander” were all Greek words to me a few months back. But it turns out that the words are essential parameters in furnace operation, which I know a bit more about now. I have realized that good furnace operation is a lot more than thermodynamics and theoretical limits.

Figure 2: Drawing that illustrate the size of a silicon furnace (note the little man in the corner). The drawing is from 'The Si Process', Drawings, by Thorsteinn Hannesson (Elkem Iceland)

I was lucky enough to get an office among the metallurgist at Thamshavn, the engineers responsible for the furnace operation. I get to follow them as they evaluate and adjust furnace parameters throughout the week, and it seems like they are happy to answer all my questions (and trust me, there is a lot of them!). Not a single day goes by without learning new things. It might sound like I am still a student, only focused on learning new things, but I do have some projects of my own as well. Estimation of furnace slag and evaluation of parameters that might affect the amount of slag is one of my main projects. Silicon balance and data analysis in general are other things that I am working on. I have already learned a great deal of new things even though I have only worked here for three months. I am really looking forward to the next five months at Thamshavn!

A bonus: Elkem Thamshavn BIL have a workshop available for members