- Magazine

- Elkem around the world

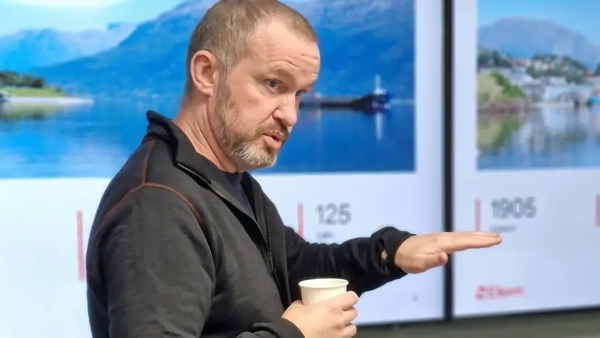

- Bjølvefossen's new plant manager: Stig Bruntveit

Bjølvefossen's new plant manager: Stig Bruntveit

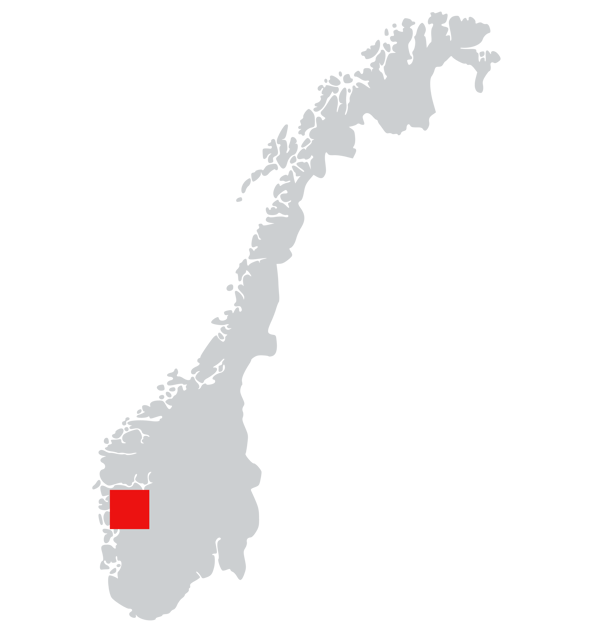

Stig Bruntveit started as plant manager at Elkem Bjølvefossen in August 2025. Since the 1920s, the plant in Kvam municipality, Norway has produced ferroalloys for the international iron and steel industry. Today, it has 160 employees and specialises in the production of ferrosilicon and magnesium–ferrosilicon master alloys.

When Elkem Bjølvefossen was looking for a new plant manager, I did not hesitate. I knew this was the job I wanted. Stig Bruntveit Plant manager, Elkem Bjølvefossen

The new plant manager has received a warm welcome and says that the most exciting part so far has been getting to know the fantastic people at, and around, the plant.

"We have many exciting projects, but it is the people who are the driving force and the most important part of our community," he says.

A cornerstone company

Elkem Bjølvefossen is the cornerstone company of the town of Ålvik, in Kvam municipality in Vestland. The plant was established in 1905, named after the waterfalls in the Bjølvo river system that supply the power for production. Since the 1920s, Bjølvefossen has produced ferroalloys for the international iron and steel industry.

Today, the plant specialises in the production of ferrosilicon (FeSi) and magnesium–ferrosilicon master alloys (FSM). It is among the world's largest producers of magnesium–ferrosilicon, delivering 120 different grades of treatment alloys and specialised FeSi products. The plant also produces Elkem Microsilica®, which is used in concrete and building boards in structures around the world.

Elkem Bjølvefossen started heat recovery in 1977, delivering surplus heat to facilities such as the nearby salmon smolt plant.

Ready for greater challenges

Stig Bruntveit grew up in a working-class family in Sunde, a small community in Kvinnherad on the west coast of Norway. His mother was a nurse, and his father worked for more than 40 years at Hydro's aluminium plant in Husnes.

"I have seen first-hand how important the coastal industrial plants, from south to north, are for the communities around them. They play a decisive role in settlement and value creation."

Bruntveit studied engineering in Haugesund. After finishing his degree, he moved to Stavanger to work in the oil and gas industry. He has held leadership and engineering roles both onshore and offshore for companies such as Aker Kvaerner, Statoil, and Norsk Hydro.

"After seventeen years in oil, gas, and maritime, and a total of ten years in Hydro's aluminium industry, I felt ready for new and greater challenges."

One thing has become clear to him throughout his career:

"Running industry in Norway that competes globally is like performing sport at an international elite level. To maintain your position, you must continuously train and develop. Our employees are our most important resource, and their efforts enable us to deliver at a top level every day."

Building a knowledge bridge across generations

Few things engage Bruntveit more than the role of Bjølvefossen, and other Elkem plants, in their local communities.

The value creation at Bjølvefossen contributes significantly to the municipality of Kvam and the wider region. For each of the plant's 160 direct jobs, more than three additional jobs are created at suppliers.

"We also have between five and ten apprentices each year, and they are an important part of our future here in Kvam. Recruiting for land-based process industry has its challenges because the plants are often located in more rural parts of Norway. As urbanisation continues, this challenge only grows."

This makes it even more important that Elkem develops skilled workers for the future.

'By taking on apprentices, we can pass on knowledge from people with 40 to 50 years of experience in the industry. This builds a knowledge bridge between generations and strengthens identity and belonging at Bjølvefossen and in the surrounding community.' Stig Bruntveit Plant manager, Elkem Bjølvefossen

Working with policymakers

At Bjølvefossen, Bruntveit has already had to navigate issues related to energy access, CO2 compensation, and access to the EU market.

"There has been industry at Bjølvefossen for 120 years, and operating in this sector has always been cyclical, with ups and downs. But since 2018, the industry has experienced a steady upswing. Many of our employees have therefore not experienced a downturn."

Lower market prices and trade restrictions that limit access to Bjølvefossen's most important market — the EU — are now affecting the plant.

"The protective measures introduced by the EU in November 2025 have naturally become a topic at the dinner table and at family gatherings here in Kvam. Many families work at Bjølvefossen — mothers, fathers, daughters, sons, aunts, uncles, and neighbours — so situations like this create uncertainty."

Bruntveit believes Elkem will need more stable framework conditions to continue operating its plants where they are today. This requires not only that politicians understand the challenges the industry faces, but also that Elkem helps them make informed decisions.

"We must explain to policymakers which framework conditions are needed to run industry in Norway. We produce specialised products priced higher than standard products, so in that sense we may be less vulnerable. But we are part of the large Elkem family, where everyone should be able to compete on equal terms with the rest of the European industry."

Continuous focus on safety

When asked about safety at the plant, Bruntveit says he is cautious about "boasting" about HSE. Elkem's operations involve inherent risks of personal injury and, in the worst case, fatal accidents. This is due in part to smelting processes with high temperatures.

"Our employees are our most important resource, and it is crucial that we work continuously on safety. It is a fresh skill that must be maintained every day."

The new plant manager says they are constantly developing technology to reduce direct contact with hazardous tasks. In addition, they work to ensure that employees and suppliers have a sense of shared ownership and contribute to making the workplace safer.

"It is about involvement, visible leadership, being a role model, and showing that you care. Most importantly, it is about seeing your employees and ensuring that they feel ownership across the organisation. Together, this is what builds the culture at Bjølvefossen," Bruntveit concludes.